Design for Manufacturability: A key milestone in the project

In today's manufacturing industry, ensuring that products are designed for cost-effective and efficient production is essential. Design for Manufacturability (DFM) is a crucial approach that helps streamline the production process, reduce costs, and improve part quality. For a manufacturing company like Kinbest, specializing in stamping, sheet metal fabrication, and CNC machining, applying DFM principles to the production of stamping molds and precision parts is key to optimizing both cost and efficiency. This article explores the critical role of DFM in stamping mold and CNC part production, and how applying these principles can result in better quality and more affordable solutions for your customers.

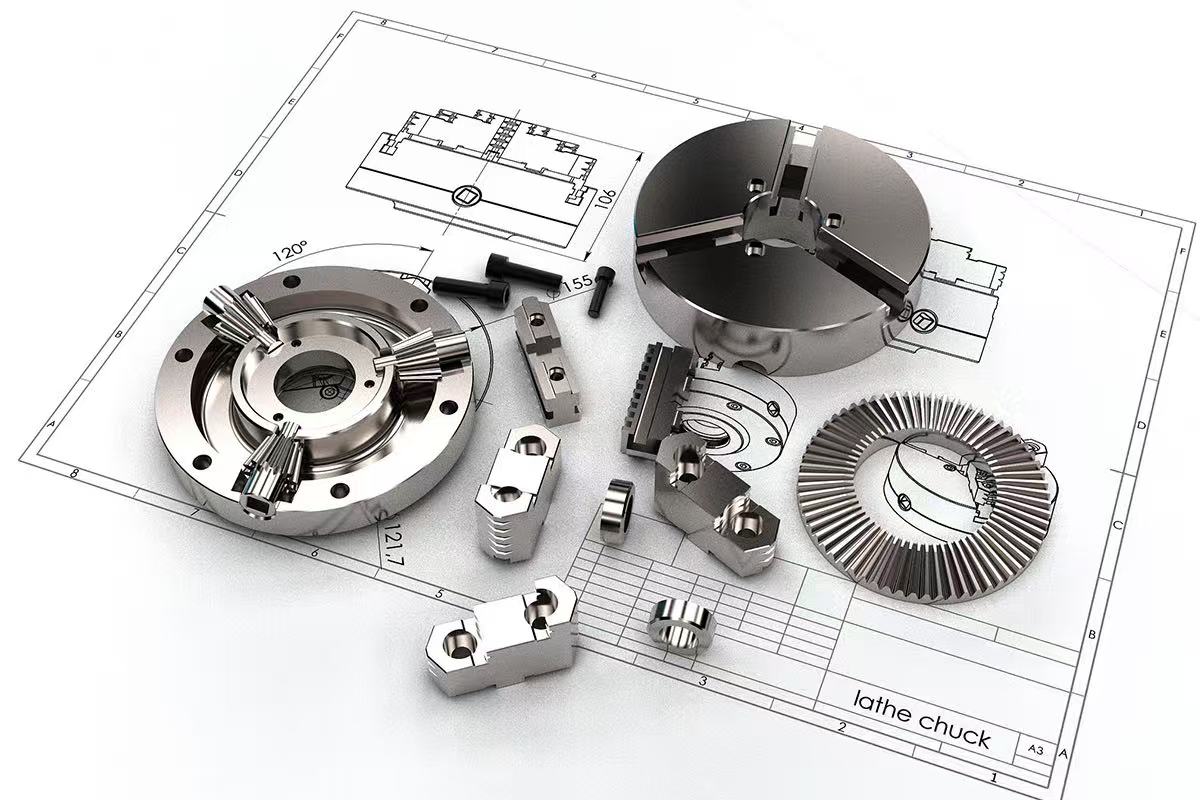

1.What is Design for Manufacturability (DFM)?

Design for Manufacturability (DFM) refers to the practice of designing parts and products with their manufacturing process in mind. The goal of DFM is to design products that are easy to manufacture at a lower cost without compromising quality or performance. By assessing the manufacturability of a part early in the design process, manufacturers can avoid costly redesigns and production delays.

DFM is not a one-size-fits-all solution but a tailored approach that considers factors like material selection, part geometry, manufacturing process compatibility, and assembly requirements. For stamping molds and CNC parts, optimizing these aspects can lead to faster production times, improved part quality, and significant cost reductions.

2.Key Elements of DFM in Stamping Mold and CNC Part Production

In the context of stamping molds and CNC parts, the following are the primary factors that influence manufacturability:

(1) Material Selection

The choice of material is one of the most important decisions in DFM. For stamping molds, durable materials like high-strength tool steels or hardened alloys are typically required to withstand high pressure and wear. However, these materials may be more challenging to machine and may require specialized processes such as CNC machining or EDM wire cutting.

On the other hand, selecting a more easily machinable material like mild steel or aluminum can lower production costs but may not provide the required strength or durability for certain applications. When designing stamping molds or CNC parts, it is important to select a material that strikes the right balance between cost, manufacturability, and performance.

(2) Part Geometry and Complexity

One of the core principles of DFM is to design parts that are as simple and efficient to produce as possible. Complex geometries, such as intricate contours, small holes, or deep cavities, may require more advanced and costly manufacturing techniques. For example, stamping molds with complex internal features or deep pockets often benefit from the use of wire EDM, which can produce fine details with high precision.

For CNC parts, optimizing part geometry involves minimizing features that require additional operations, such as intricate holes or sharp corners. The goal is to design parts that can be machined with fewer tool changes or special fixtures, reducing setup time and overall production cost.

(3) Tolerance and Finish Requirements

Parts with tighter tolerance requirements are more difficult to manufacture and typically require more advanced, precise techniques. For example, stamping molds and CNC parts used in high-precision industries (such as aerospace or medical device manufacturing) must meet stringent tolerance specifications to ensure proper functionality.

DFM encourages evaluating whether such tight tolerances are necessary for the part's intended function. In some cases, relaxing the tolerance can result in significant cost savings without compromising the part’s performance. For example, some parts may function adequately with looser tolerances, allowing manufacturers to use faster, less expensive processes.

(4) Manufacturing Process Selection

The selected manufacturing process must align with the design of the part. For stamping molds, a typical workflow includes CNC machining for rough shaping, wire EDM for intricate features, and surface treatments or heat treatments for finishing. These processes must be carefully considered to ensure that they are both efficient and cost-effective.

For CNC parts, the geometry of the part dictates the machining process. If the part has simple features, traditional 3-axis milling or turning may suffice. However, for more complex geometries, multi-axis CNC machining may be required. DFM principles help determine the optimal manufacturing process based on the part's design, the material chosen, and the desired production speed.

(5) Ease of Assembly

For parts that require assembly, DFM involves designing components that are easy to align, join, and secure during the assembly process. The more complex and time-consuming the assembly, the higher the overall production cost. Simplifying part design can reduce assembly time, minimize the need for additional fasteners, and make the assembly process smoother.

In the context of stamping molds, ease of assembly means designing features that align easily and reduce the need for custom fixtures or adjustments during assembly. This is critical for ensuring the mold can be quickly and accurately set up for production.

3.DFM for Stamping Molds: Optimizing Performance and Reducing Costs

Stamping molds are integral to industries such as automotive, electronics, and medical device manufacturing. These molds must be highly precise and durable to produce high-quality parts in large volumes. Applying DFM principles to stamping mold design can significantly improve efficiency and reduce costs:

(1) Simplifying Tooling and Operations

Stamping molds typically undergo several stages of manufacturing, including CNC machining, wire EDM, surface treatments, and sometimes hardening processes. DFM encourages designing molds that require fewer operations or simpler tooling setups. For instance, optimizing the geometry of the mold to minimize deep cavities or undercuts can reduce the need for specialized tools or complex machining processes.

(2) Optimizing Material Usage

Material waste is one of the biggest contributors to high production costs. In DFM, the layout of the stamping mold cavities is carefully planned to ensure efficient material usage, reducing waste and lowering overall costs. Advanced CAD tools and simulations are often used to identify the most efficient way to design and manufacture the mold, ensuring minimal material consumption.

(3) Precision and Detail in Mold Features

Features such as small holes, sharp edges, and complex geometries are common in stamping molds. These features require high-precision manufacturing methods such as wire EDM to achieve the desired results. DFM ensures that such features are considered early in the design phase, allowing for the correct manufacturing processes to be selected and ensuring the mold meets the required specifications.

4.DFM for CNC Part Production: Reducing Complexity and Improving Efficiency

CNC machining is an essential process for producing high-precision parts with complex geometries. By applying DFM principles to CNC part design, manufacturers can streamline production and improve overall efficiency:

(1) Optimizing Part Geometry for Machining

Parts with complex geometries, such as intricate curves or deep pockets, may require multi-axis CNC machining. DFM encourages designers to minimize complexity wherever possible. For example, designing parts with simpler features or combining multiple parts into one can reduce machining time and the need for special tools or setups.

(2) Minimizing Tool Changes and Setups

Reducing the number of tool changes and fixture setups is one of the main goals of DFM in CNC machining. Parts designed with uniform features, such as simple holes, slots, and edges, can be machined more efficiently with fewer tool changes. This not only speeds up production but also reduces tool wear and machine downtime.

(3) Surface Finishing and Post-Processing

Many CNC parts require additional surface finishing or post-processing steps, such as coating, heat treatment, or polishing. DFM focuses on designing parts that minimize the need for post-processing, ensuring a smoother and quicker manufacturing workflow. For example, designing parts with a smooth surface finish directly from the CNC machining process reduces the need for extensive polishing or coating operations.

5.The Benefits of DFM for Stamping Molds and CNC Parts

(1) Cost Reduction

By optimizing material selection, part geometry, and manufacturing processes, DFM helps reduce the overall cost of producing stamping molds and CNC parts. Reducing material waste, minimizing machining time, and simplifying the assembly process all contribute to lower production costs.

(2) Faster Production Times

DFM allows manufacturers to streamline production, ensuring that parts are produced more quickly. Whether it's simplifying the geometry of a stamping mold or reducing tool changes in CNC machining, DFM reduces lead times, helping you meet customer deadlines faster.

(3) Improved Quality and Consistency

Designing with manufacturability in mind reduces the likelihood of defects and ensures that parts are produced consistently within tight tolerances. For stamping molds and CNC parts, this results in higher-quality products that meet the desired specifications, reducing the need for rework or scrap.

(4) Enhanced Flexibility

DFM makes the production process more flexible by evaluating multiple manufacturing methods and selecting the most appropriate one for the part. This allows manufacturers to adjust their processes based on the part's design and performance requirements, increasing their ability to handle a wide range of products.

6.Summary

Design for Manufacturability (DFM) is essential for optimizing the production of stamping molds and CNC parts. By considering factors like material selection, part geometry, tolerance requirements, and manufacturing processes early in the design phase, manufacturers can reduce costs, improve quality, and shorten production times. Kinbest applies DFM principles to every project, ensuring that each part is designed to be cost-effective, high-quality, and manufacturable. If you need assistance with DFM for your stamping molds or CNC parts, contact us today to learn more about how we can optimize your production processes.