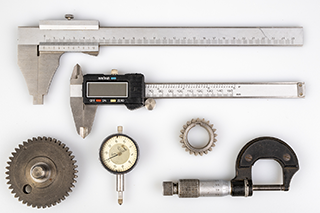

Quality Management System

Our QMS, based on ISO 9001, IATF 16949, and ISO 13485, ensures product excellence from design to delivery. With standardized processes, regular audits, and detailed documentation, we maintain consistency and traceability. Continuous improvement through SPC and FMEA, along with regular team training, ensures high-quality, reliable products for the automotive and medical device industries.