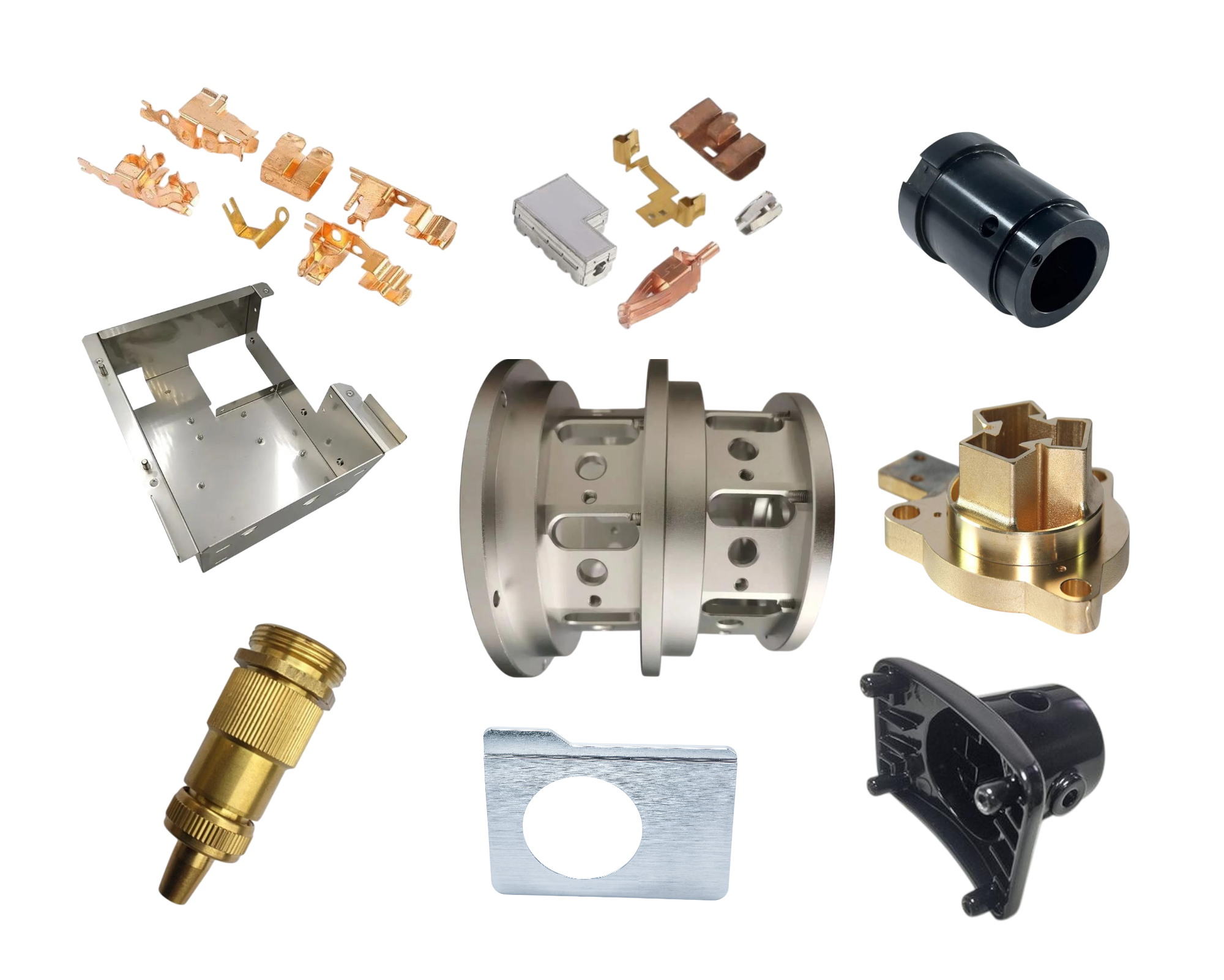

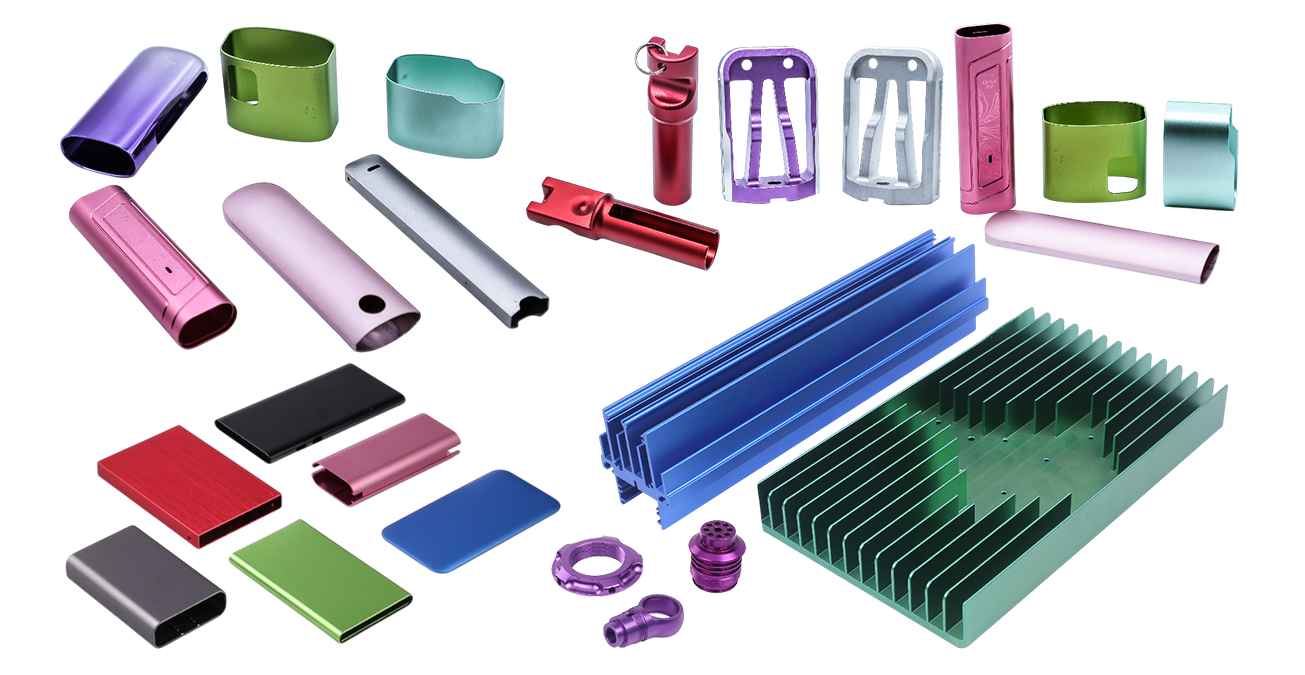

Anodizing

Anodizing creates a hard, protective oxide layer on aluminum surfaces, improving corrosion resistance, wear resistance, and surface hardness. It also enhances weatherability and coating adhesion, with options for different colors, suitable for durable and decorative applications.