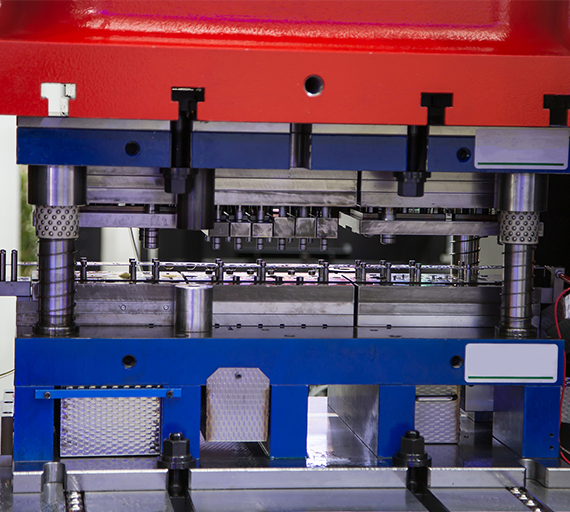

One-Stop Mold to Mass Production Solution

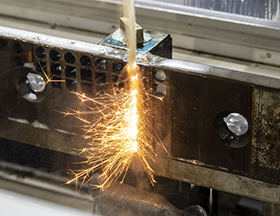

Precision Design: Using CAD/CAM software and appropriate engineering techniques to ensure the mold structure and functionality meet high precision requirements.

Expert Team: Senior engineers handle design, manufacturing, and debugging for high-quality results.

Strict Quality Control: Rigorous control from raw material to production ensures stability and durability.

Regular Maintenance: Regular checks and maintenance to extend mold life and ensure efficient production.

Fast Production

High-quality stamping molds with quick turnaround.

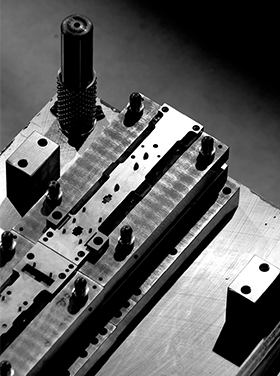

Custom Molds

Tailored solutions for your specific needs.