Advantage

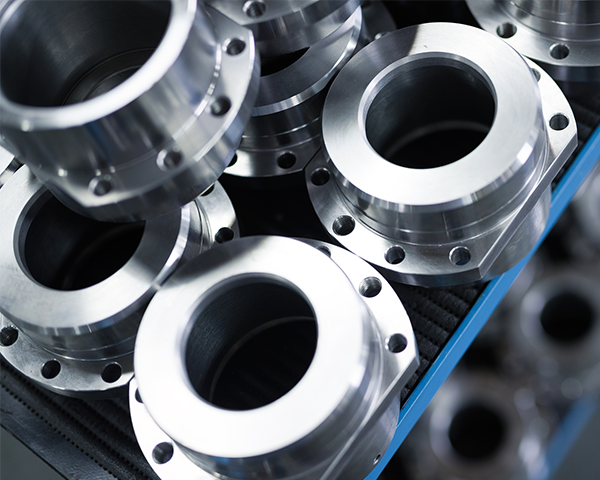

Powerful Solutions for Your Projects

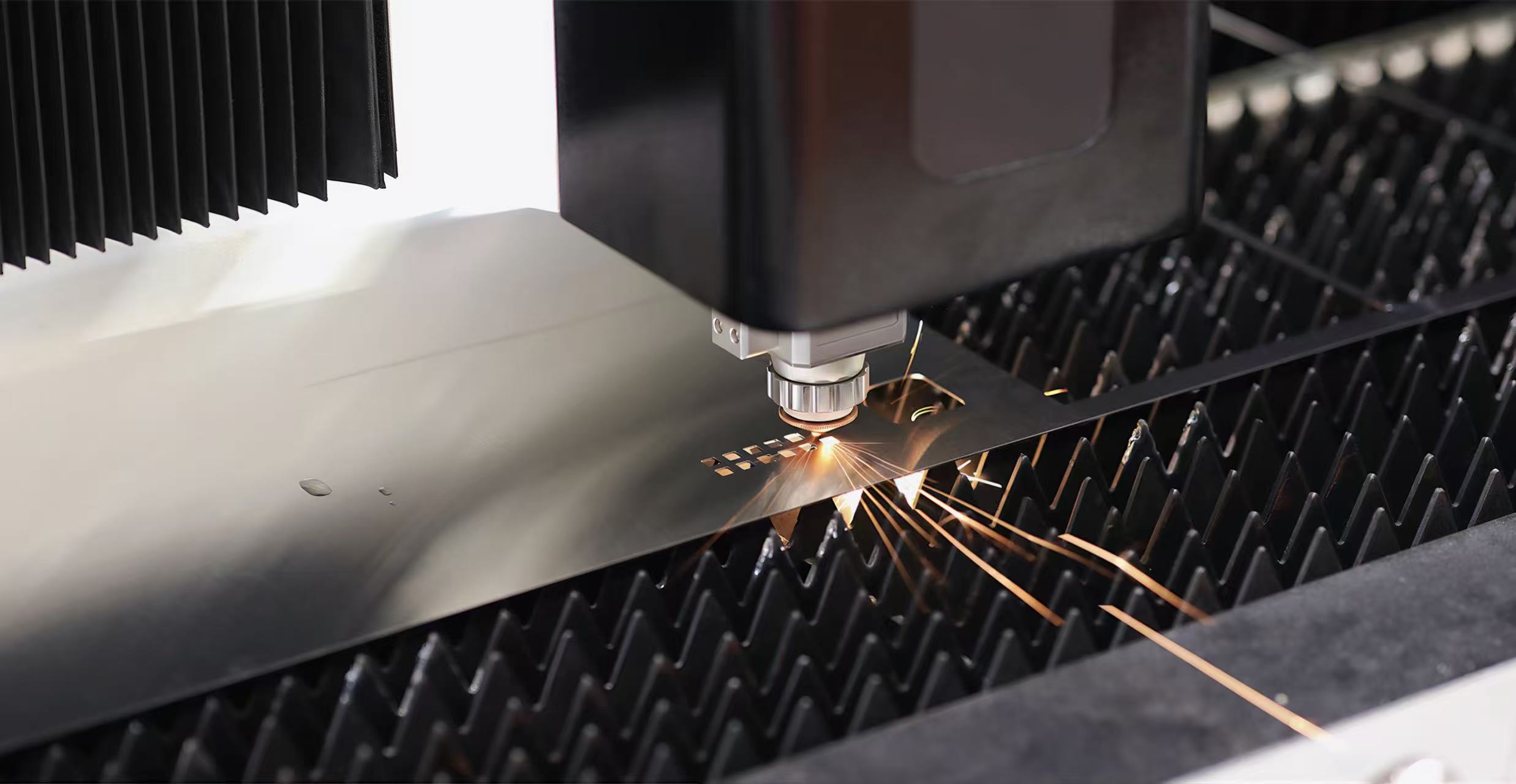

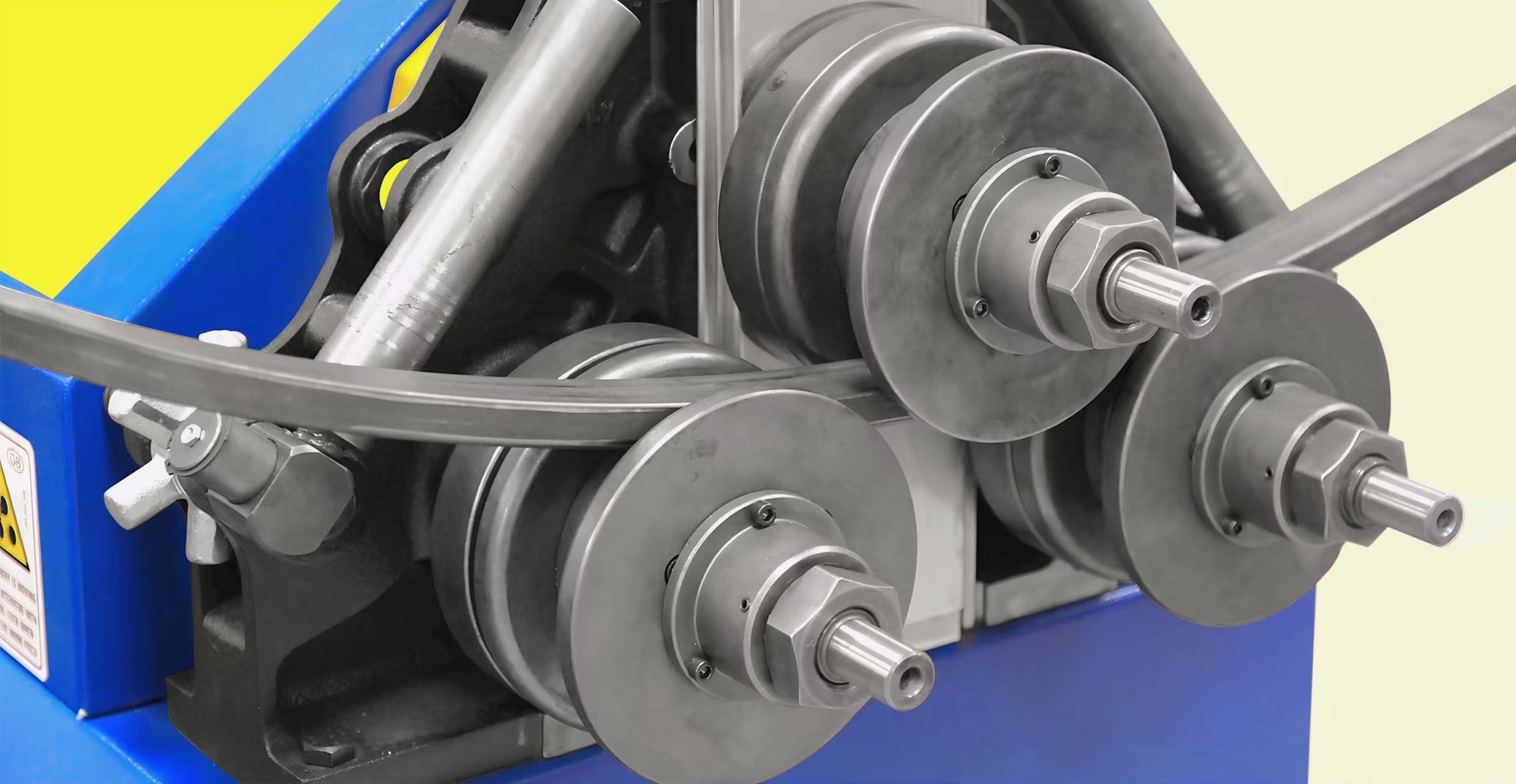

Rapidly produce high-quality custom parts through the flexible, integrated architecture of our Advanced Manufacturing Solutions.

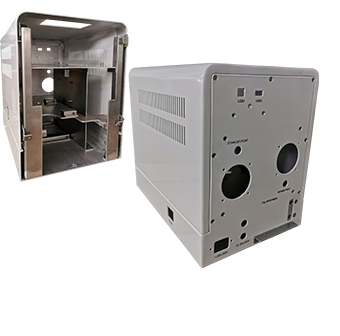

Design to Scaled Production

We support your entire product development journey — from early design consultation and cost-optimized engineering, to prototype verification, low-volume testing, and stable batch production.

Efficiency with Accountability

Every part is manufactured, inspected, and delivered according to exact customer specifications. Our diversified production processes adapt to different MOQ needs, ensuring cost-efficiency, flexibility, and reliable lead times.