One-Stop Mechanical Parts Manufacturing Factory

With nearly three decades of experience, Kinbest provides on-demand manufacturing solutions from prototyping to mass production.

Parts in as fast as 5 days

No Minimun Order Quantities

IATF 16949:2016 & ISO 13485:2016 Certified

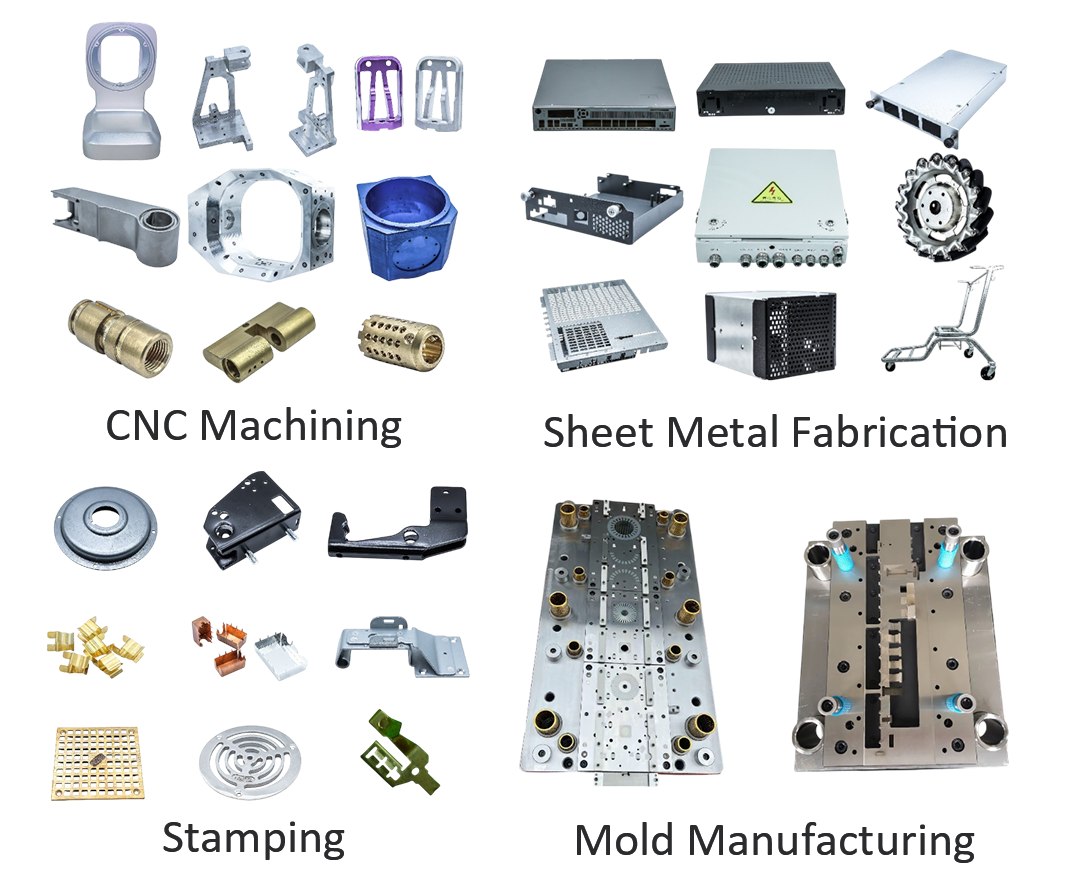

Stamping

Sheet Metal Fabrication

CNC Machining

Precision Mold Manufacturing

Trusted by engineers at